Just when you thought separation processes could not be more drawn out, dewaxing appears! Undoubtedly another slightly misleading process title, dewaxing is chiefly concerning the lubricating oil base stock product more so than the wax byproduct. The lube oil base stock market price depends on its volatility, viscosity, viscosity index, and thermal stability. Depending on the process employed, the resultant lube oil base stock may not require as many additives to enhance engine performance.

Solvent dewaxing requires a tremendous amount of energy and solvent to remove wax from the lube oil base stock. We discussed the use of solvents such as methyl ethyl ketone and propane along with the need for refrigeration units and steam-stripping to remove wax. Bechtel Corp. displays a general layout of its own solvent dewaxing process. Notably, Bechtel uses inert gas instead of energy-intensive steam for stripping. Regardless, the operating costs illustrate how significant the dewaxing footprint is within the refinery. No wonder those oil leaks cost me a fortune!

You may question the utility of wax on the open market, like I do. Never fear, catalytic dewaxing is here!

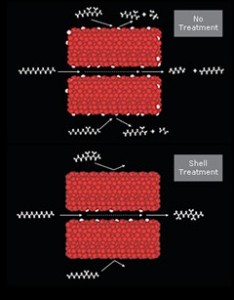

Shell Global Solutions’ website illustrates the company’s catalytic dewaxing technology for the work to study (and purchase). This separation process actually involves catalytic cracking of n-paraffins using a selective catalyst. To mitigate fouling of the catalyst, hydrogen is also applied. This process enables the operator to produce even more distillates and lube oil base stock. This is tremendously lucrative since it requires a lower capital investment; the selection of this process relies on the robustness and effectiveness of the catalyst. Perhaps, I should invest in the catalyst industry…

Fig. 1: Shell Global Solutions’ proprietary catalyst (Source)

Fig. 1: Shell Global Solutions’ proprietary catalyst (Source)