Ever since the first oil well was drilled in 1859, there has been an increased demand in petroleum in the United States.1 This is because petroleum was found to have many different uses since it could have different properties depending on what temperatures the petroleum was distilled at. In order to do this process, oil refineries were built in order to get useful products while removing the harmful side products of the process. The first refinery in the United States was opened in 1861.1 This shows that people saw the importance of processing the petroleum and moved quickly to build a refinery to do so. With the invention of the internal combustion engine the demand for gasoline has grown dramatically over the years.

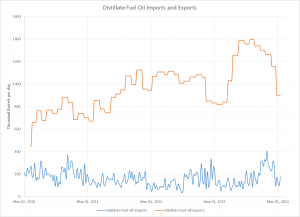

In 2013 the United States had a total oil production of 12.316 million barrels.2 Even though this is a large amount that was produced, it was still less than the consumption of 18.49 million barrels in 2013.2 Therefore the United States needed to import oil in order to meet this demand. Data from 2012 shows that approximately 40% of the petroleum consumed was from exports.3 Surprisingly a little over 50% of the imports came from the Western Hemisphere with Canada being the largest crude oil supplier to the United States.3 This shows that there is less of a demand in the political unrest in the Middle Eastern region. Since 2005 the demand for imported oil has declined. After the recession in 2008 the consumption of oil was lesser and there was a focus on increasing the efficiency as well as the increase in the use of biofuels such as ethanol and biodiesel.3 The discovery of the Marcellus and Utica Shale formations in Pennsylvania has led to the finding of tight oil that adds to the total oil reserves in the United States, which makes it possible for the United States to import less.6

In 2012 37% of energy in the United States came from the consumption of petroleum.4 Even though renewable fuels and natural gas are having a greater impact, petroleum is still the largest energy source. This means that oil refineries have a large job to fulfill. The refineries have the capacity to process large amounts of crude oil, but also must take into consideration the environmental impact that the refineries have. Refineries consume a large amount themselves as they are distilling the crude oil to form the final products. There are restrictions on the CO2 emissions as well as on the hazardous byproducts of the process. When petroleum products are burned in an internal combustion engine several harmful products are created. These include carbon dioxide, which is a greenhouse gas, carbon monoxide, sulfur dioxide, which contributes to acid rain, nitrogen oxides, volatile organic compounds, and particulate matter.5 All of these negatively impact the environment and human health. Therefore the government strictly enforcing regulations on refineries and how they process the crude oil in order to limit the harmful byproducts. It does not mean there will be a large decrease in the consumption of petroleum fuels in internal combustion engines, but that refineries will be forces to formulate the fuels in a way that limit the environmental and health concerns.

References

1.) Gary, James H., Handwerk, Glenn E., Kaiser, Mark J. Petroleum Refining Technology and Economics. Taylor and Francis Group. Florida. 2007. Print.

2.) http://www.eia.gov/countries/country-data.cfm?fips=US

3.) http://www.eia.gov/energy_in_brief/article/foreign_oil_dependence.cfm

4.) http://www.eia.gov/forecasts/aeo/er/early_fuel.cfm

5.) http://www.eia.gov/energyexplained/index.cfm?page=oil_environment

6.) http://www.eia.gov/tools/faqs/faq.cfm?id=847&t=6