Blog 4

Write a post explaining how solvent fractionation works and review the parameters to describe the solvent power for non-polar solvents.

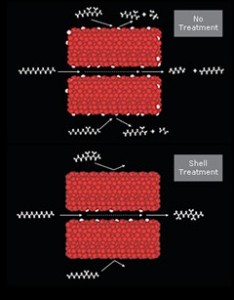

Through the process of deasphalting, a solvent is used to fractionate various feedstocks. Deasphalting performs its fractionations based upon the components of solubility and insolubility of feedstocks where distillation uses the boiling point temperatures to make fractionations. Vacuum distillation residue, known as VDR, is completely dissolved in aromatic solvents such as toluene and benzene. VDR is typically in the form of a solid at room temperature so then the aromatic solvents are used to create a liquid mixture where a light paraffin solvent is mixed with the feedstock mixture to precipitate the VDR asphaltene. Depending upon solubility the asphaltene is then separated from the mixture.The VDR component that is soluble in this light paraffin is referred to as a maltene and is considered a one phase material solution. Through the gradient solubility model it is explained that asphaltene molecules can dissolve and give a single phase solution. Through solvent extraction and VDR the asphaltene can be removed from the solution.

The VDR compounds solubility, which effects the extraction, depends on the strength of the solvent which is measured for non-polar solvents by the Hildebrand Solubility Parameters, also known as HSP. There are two different Hildebrand solubility parameters that affect this solubility. The first parameter measures the relationship between surface tension and the cube root of molar volume. These happen to have an inverse relationship where surface tension increases with decreasing molar volume. Solubility also increases with surface tension. The second parameter measures solubility based upon the relationship between the heat energy required for vaporization and the molar volume. This is typically calculated under constant volume. Solubility increases in this case with an increase in the amount of energy for vaporization.